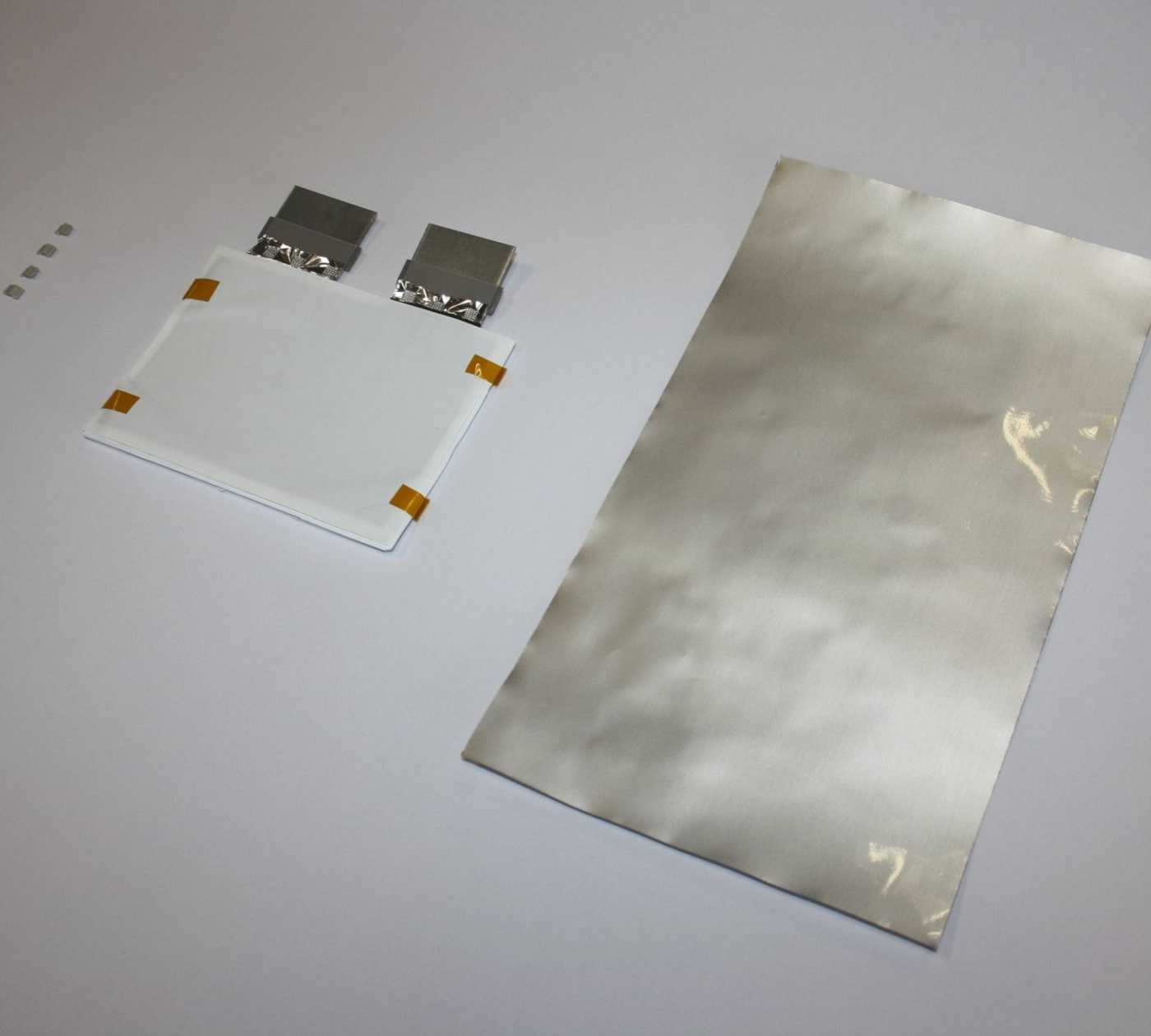

Pouch with port

Our Smart Battery Innovation

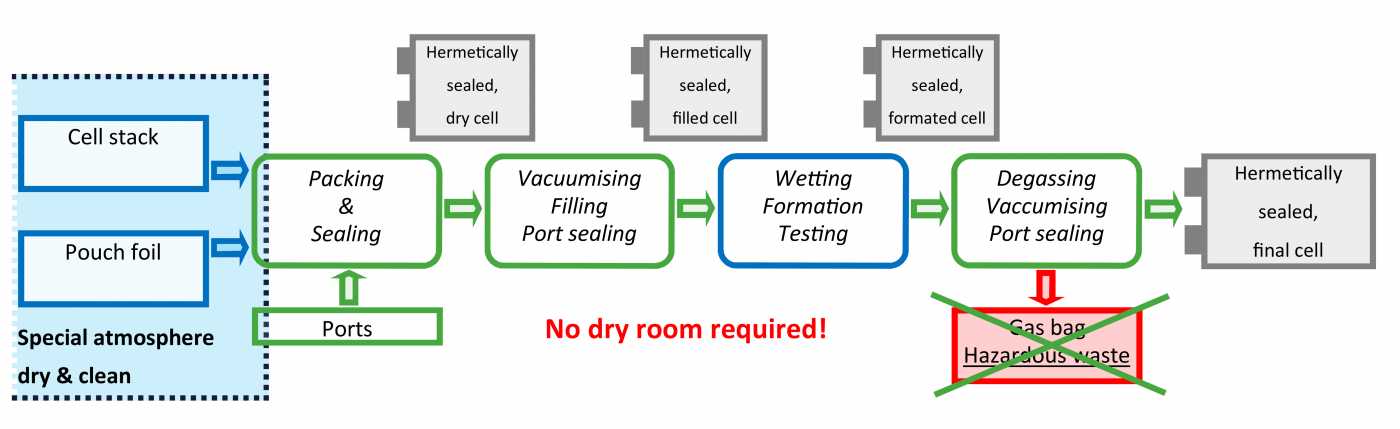

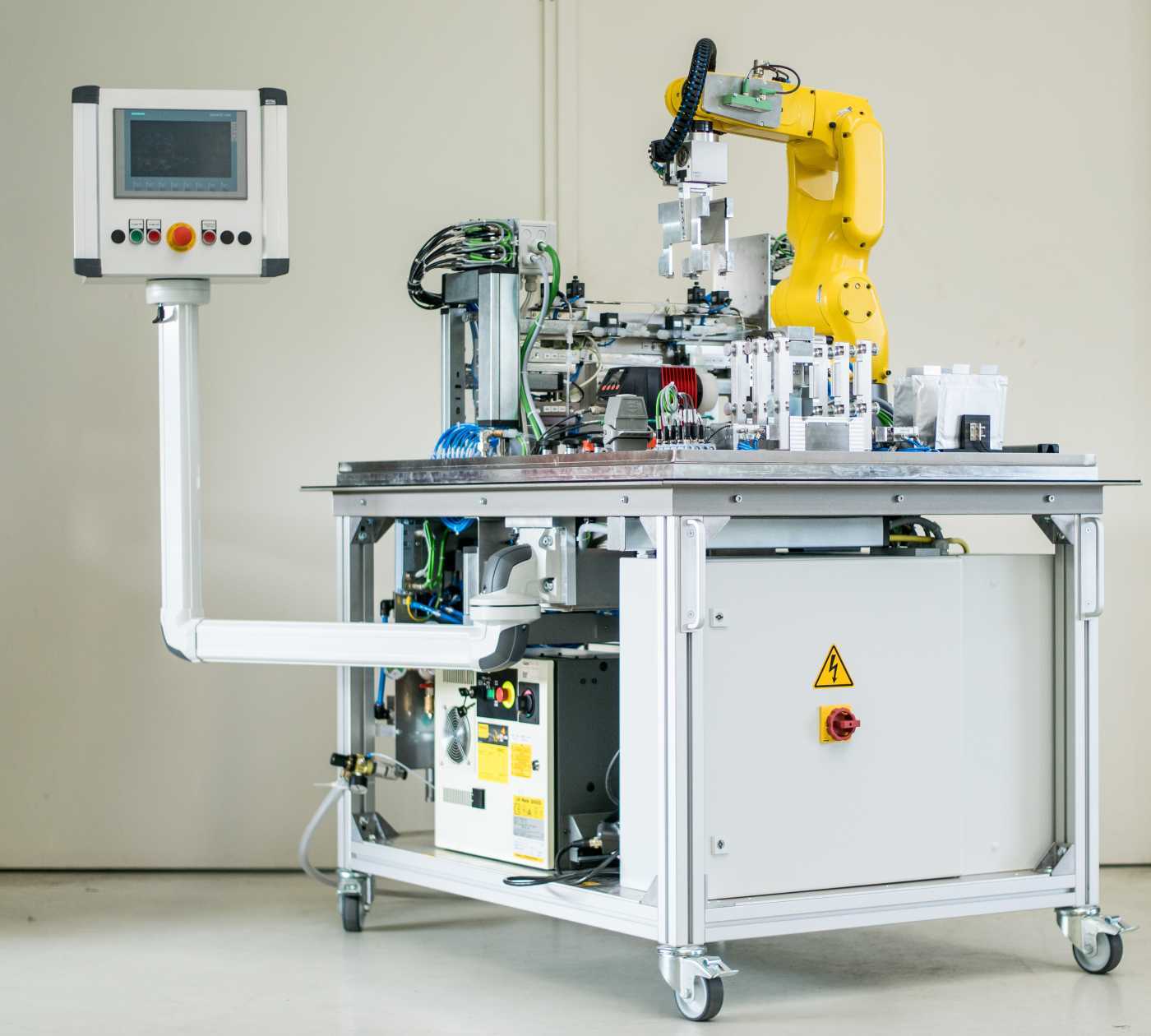

Our novel technology for electrolyte filling does not require a dry room and also enables a quick and optimal wetting. The innovative concept offers great potential for saving energy, materials and costs as well as reducing the CO2 footprint. The patent is granted.

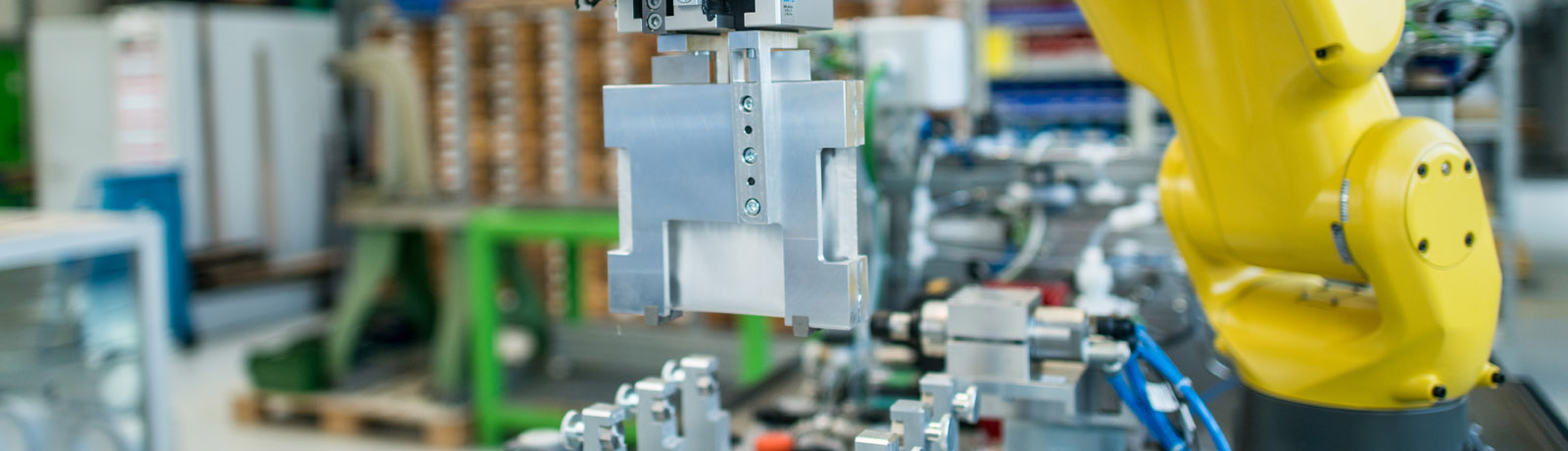

The port technology consists of pouch sealing including ports as well as filling and degassing via the ports after formation without need of a gas bag. We developed a technology for degassing simultaneously to formation (patent pending).

Our innovative and patended production process delivers advantageous solutions for the most problematic issues of conventional pouch filling, which are:

- The pouch foil is 30-50 % larger than the final cell to form the gas bag.

► unnecessary material costs - The open cell needs to be handled in dry atmosphere.

► huge investment and operating costs - The contaminated gas bag needs to be cut off and disposed.

► extensive disposal effort

Our Solutions:

- Filling at ambient atmosphere

- Pouch without excessive amount of foil

- No contaminated gas bag

- Variation of filling strategies possible

- No vacuum chamber is needed in the machine

- Readjusting of electrolyte quantity after formation/degassing possible

Unique advantages:

- Reduction of invest/operating costs and CO2 polution

- Reduction of material costs per cell

- Reduction of effort for disposal

- Faster and homogeneous wetting

- Plain machine design, improved wetting

- Process flexibility granted